Why Brand?

In prototype manuafcturing field, suppliers are of variable quality. When an engineer or a desinger looks for a prototype maker to help him to make his ideal to real, there isn’t a name coming to his brain. They don’t know how it is good or bad of a prototype supplier which they just searched from google. Just like we want a express, we call DHL, UPS or FedEx. That is the power of a brand. We just know they are best. So WeLink separate its rapid manufacturing to a new brand — ProtoWe.

Mission on ProtoWe

ProtoWe is a WeLink brand in global rapid manufacturing. Inheriting WeLink’s reputation of “Proud of Quality and Cheap”, clients can always benefit from our excellent quality, cheap, fast and services. Quality & Cheap is the blood in ProtoWe, it is where we are from and where we are going. ProtoWe is not a short-term profit maximized company, but a brand to lead the industry and consistently provide volume to our global manuacturing clients. ProtoWe will be a brand well-know in rapid manufacturing field, ” Make prorotypes with ProtoWe” is a pet phrase around the designers and engineers. ProtoWe hopes clients come from Cheap, go back with Quality.

Services in ProtoWe

ProtoWe provides one-stop rapid prototyping, rapid manufacturing and low volume manufacturing from China to global clients. “Quality and Cheap” in blood, we export rapid prototypes made of CNC machining, SLA/SLS 3D printing, Vacuum casting, sheet metal to global clients. We have rich experience in materials hard plastics, soft plastics, silicone and rubber, aluminum, stainless steel, copper, zinc, carbon fiber etc. but not limited. We have imported advanced 3/4/5 axis CNC milling centers can deal with +/-0.005 mm tight tolerance parts. What’s more worth mentioning is, we have 50+ SLA printers, and the max whole print size is 1,600 mm long. Rapid tooling and Rapid molding is a very special and core advantage service in ProtoWe, amazing 3-7 days for 500~1,000 units and global delivery. In a word, prototyping with ProtoWe, come from cheap, back with quality.

3D Printed Prototype

ProtoWe provides SLA/SLS/SLM 3D printing prototyping services since 2016. Now we are leading in SLA 3D printing prototyping in China. By 2020, ProtoWe has 100+ SLA printers, and the max whole print size is as long as 1,600 mm. We have 10 sets of HP SLS printers to print PA/Nylon material or with GF. The PA parts have very micromish and pyknotic surface and great strength. For SLM printing, we have 3 sets printer, main print some mold steel and stainless steel.

- 100+ SLA printers, Max whole workpiece 1,600 mm

- 10+ SLS HP printers, good surface quality

- SLA materials: ABS like, ABS 8150, Nylon like (Somos EvoLVe 128)

- Materials: PA white, PA black, PA gray

CNC Machined Prototype

At PrototWe, CNC Machining prototype is our traditional and core service. Each year, hundreds of thousands of quality CNC machined parts export from China to global clients. Our CNC machining service covers CNC Milling prototype, CNC Turning prototype, EDM machining and small batch manufacturing. We machine various materials: aluminum, stainless steel, mold steel, copper, zinc, plastic etc.

- 30 sets of 3-4 axis CNC Millers, 2 sets of 5 axis CNC Millers, tolerance +/-0.005 mm

- 5 sets of CNC turning machines, high precision +/- 0.002 mm

- 3 sets of EDM machines, make up for CNC milling services

- Support in-house CMM dimension reports

Vacuum Casted Prototype

At PrototWe, Vacuum Casting is used to make insert molding parts, soft plastics, sillione/rubber, transparent parts in one or several pieces, or make a small batch plastic parts instead of steel or aluminum mold making. It is a economical and efficient way to get 10-30 units per silicone mold, and 50-200 units by several silicone molds.

- Part Size: 10 ~ 3,000 mm

- PU material: ABS like, PA like, PP like, PC like, PMMA like, POM like, ABS UL-94 V, Glass Fiber..

- Material Vendor: AXSON, Hei-Cast, etc.

- Lead Time: 2-3 days

Sheet Metal Prototype

In ProtoWe’s sheet metal workshop, there are complete machines for a precision sheet metal prototype. The machines include laser cutting machine, bending machine, cutting machine, hole flanging machine, drilling machine, CNC miller, punching machine, welding machine etc. The core machines are:

- Laser cutting machine

- Bending machine

- Hole flanging machine

- CNC milling machine

- Punching machine

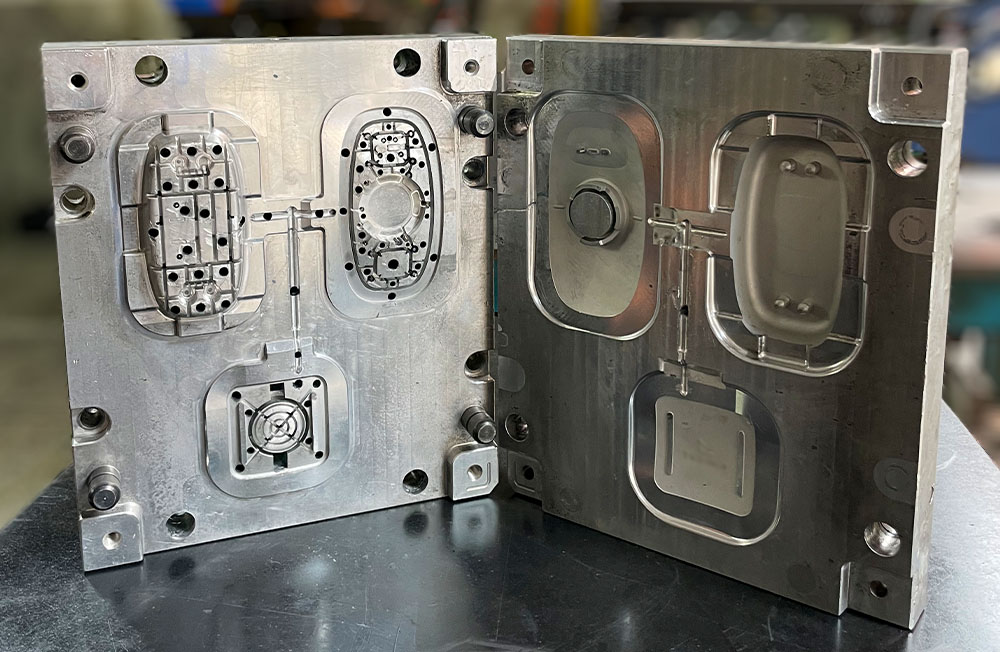

Rapid Tooling China

Our advantage on rapid tooling thanks to ProtoWe’s attention and technology development and years of experience accumulation. Eventually these advantages make very short lead time and much lower cost.

- A mass of universal and shared mold bases

- Hand inserts instead of any sliders and lifters

- Simplified parting line

- Plenty of standard size Aluminum and P20 in store

- Working 24h/d & 7d/w

Low Volume Manufacturing China

Not only one or several prototypes, ProtoWe provides our clients low volume manufacturing from 100 to 1,000 units, from 500 to 10,000 pieces. With our experience and advantage, we support our clients quality, cheap and short lead time small batch manufacturing parts or products. These manufacturing technologies include rapid injection molding, vacuum casting, CNC machining, 3D printing, sheet metal and more.