Rapid Tooling

What is rapid tooling?

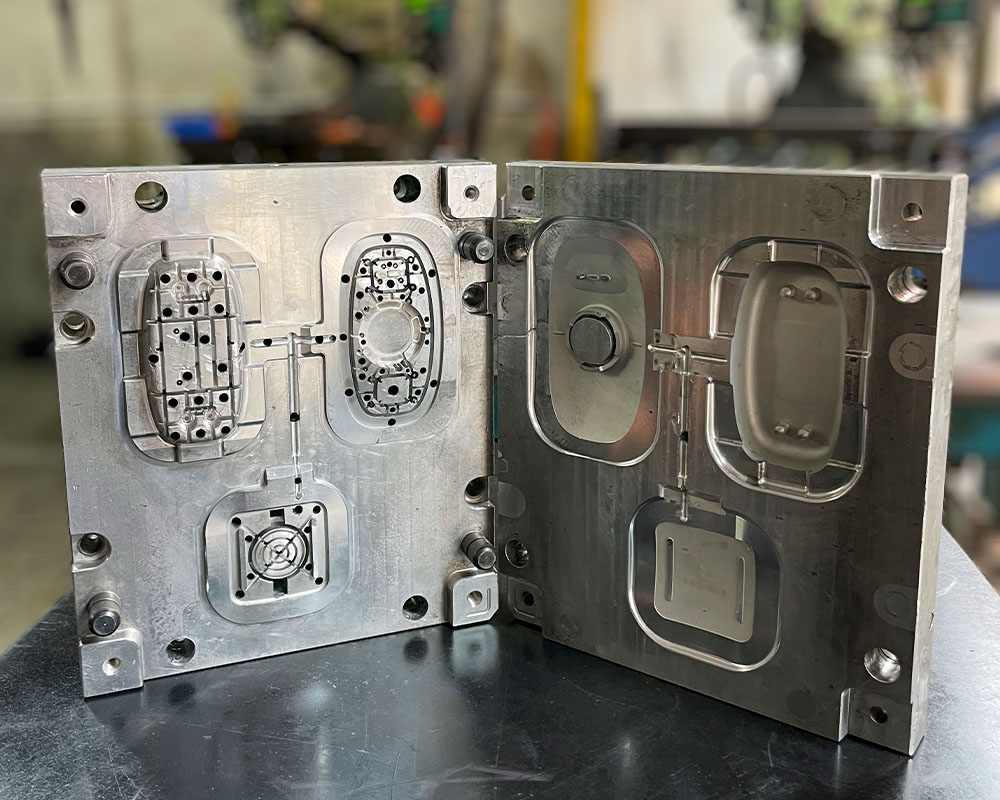

The rapid mold is also called the prototype mold, which is a very cheap mold that is manufactured at the fastest speed with a simple mold structure. In some head rapid mold companies, rapid mold making can be achieved in 3-7 days, and rapid injection molding can be completed in 1-3 days. Compared with the production volume of hundreds of thousands of traditional production molds, rapid molds generally only produce a few hundred to a few thousand products. Its purpose is to quickly verify products and deliver products in small batches at the lowest cost.

How is the rapid mold made specifically?

First of all, the steel for rapid molds is usually 7075 aluminum alloy or mild steel such as 1.1730 or 1.2311, so that the material is cheap, the processing speed is fast, and the processing cost is low. Secondly, the rapid mold structure and its simplification. Compared with traditional mass production injection molds, rapid molds do not use row positions and inclined tops. Instead, manual demolding inserts are used instead, and almost all mold parts are omitted, which also shortens mold manufacturing. Time and cost. Third, rapid molds use simple common mold blanks. A standard mold blank can be used repeatedly for many molds, which also reduces mold costs.

What are the advantages of rapid tooling?

From the above description, it is not difficult to see that compared with traditional mold manufacturing, the advantages of rapid mold manufacturing are quite obvious:

- The mold production cycle is fast. Rapid molds can complete mold production in 3-5 days, while traditional molds require 30 days.

- The cost of rapid tooling is low. Because the rapid mold simplifies the mold structure, uses cheap mold steel, and the shared use of mold bases, the rapid mold can save 40%-50% of the cost compared with traditional molds.

Application of rapid tooling

At present, rapid dies are used in all walks of life, but they are especially widely used in the automotive industry. The most widely used rapid tooling in the automotive industry has a lot to do with the characteristics of the automotive industry.

1. The production of auto parts is more rigorous. Before the car goes on the market, the parts are repeatedly tested and verified, which requires a large number of real injection molded parts, rather than 3D printing, CNC processing or vacuum complex molding production of non-real functional structural parts.2. The structure of automobile parts is complex. If normal molds are used in the experiment stage, the cost of the experiment will increase exponentially, and the verification time will also increase exponentially.

The above is some of my understanding of rapid mould based on my own industry experience. If you are interested, you can get to know our company. We are a very professional Rapid Tooling China company, with more than 10 years of experience in rapid mold manufacturing for auto parts, rapid mold production in 3 days, and 50% cost savings.